TMT Fleet Maintenance

TMT Fleet Maintenance is an Asset Maintenance System for managing equipment from a Repair and Maintenance standpoint. While TruckMate has its own Repairs & Maintenance module, this integration allows the use of TMT Fleet Maintenance in its place.

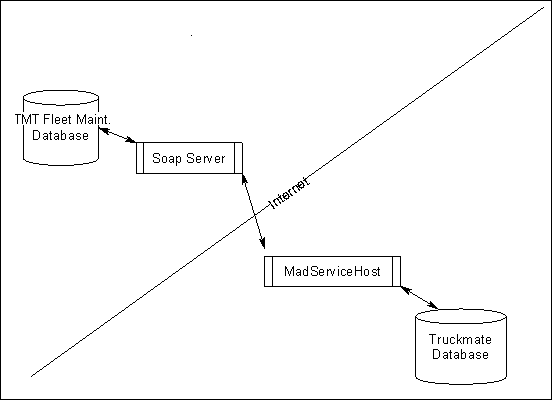

System Components

TMT Fleet Maintenance makes its database available through a Soap Server. This is an application that allows TruckMate to request and update specific sets of data through a secure interface.

TruckMate Service Host program

The TruckMate Service Host program (MADSERVICEHOST.EXE) is a TruckMate application that runs various mobile communication tasks. One of these tasks is to periodically transfer data between the Soap Server and the TruckMate database.

The Queue View window shows the jobs that are currently in the queue. The queue is essentially a task list which shows the tasks that the thread is scheduled to perform. Once the thread is running, it performs the jobs that are in its queue. Each job has an activation time, which is the time it is supposed to execute.

Some jobs have an interval period. This period indicates that the job is repeatable and once activated, will reactivate after the specified interval.

Other jobs are "one time" jobs, that is, once they activate, they do not automatically repeat. Typically, "one time" jobs are added to the queue by periodic jobs.

The Activity Log window shows the results of jobs. It reports status issues, errors, etc. You can change the message level to filter out low level messages. It is possible to save the log to a file for later analysis.

Note: For more information on using the TMT Module Properties window to setup the integration with TruckMate, refer to the TruckMate Service Host program help text.

TruckMate & TMT Fleet Maintenance Integration Points

The integration between TruckMate and TMT is done across the following integration points:

-

Adding New Assets: When new assets are added in TruckMate they are detected by the interface and automatically added to the TMT Fleet Maintenance database. Also, when new assets are loaded into the TMT Fleet Maintenance system they are transferred automatically to the TruckMate database.

-

Meter Readings: Meter readings are transferred from TruckMate to the TMT Fleet Maintenance which will drive the Preventive Maintenance scheduling for your equipment.

-

Moving Equipment Assets: When equipment assets are moved in the TruckMate system the location of the asset is updated in TMT Fleet Maintenance.

-

Maintenance Orders: All TMT Fleet Maintenance orders are passed directly to the TruckMate accounting system. Purchase Orders are passed to Accounts Payable, Repair Invoices are passed to Accounts Receivable, and Repair Order costs are passed to the General Ledger.

-

Pending Repair Orders: TruckMate pulls a list of work pending Repair Orders from the TMT Fleet Maintenance program so the dispatch operations are aware of work that needs to be performed and can more easily route the equipment to a shop for repairs.

-

Status Reporting: The TruckMate TMT Fleet Maintenance interface takes planned PMs, Repair Orders, Work Pending and Out of Service status and sends them to TruckMate. The interface does this by polling the units status and reporting it back to TruckMate. The three statuses are:

-

Active - this means that the unit has no plans, work pending, or repair orders open for it. The unit is free to be dispatch in TruckMate.

-

In-shop - this status indicates that the unit has an open Repair Order and is currently being worked on. This unit cannot be dispatched in TruckMate.

-

Plan - this status indicates that a Plan has been created in Shop Planner. The plan can be for a PM or Repair Order, when the plan is created it will create a Special Event in TruckMate.

-

TMT Fleet Maintenance Jobs

Repeatable Jobs

-

Clean Job table: periodically flushes certain TruckMate tables to prevent them from growing too large.

-

Update Master Files: looks for changes in TruckMate asset tables. If any new entries are found, then "one time" jobs are spawned to upload each asset to TMT Fleet Maintenance.

-

Check TMT Fleet Maintenance Job: retrieves new asset list from TMT Fleet Maintenance. If any are found, "one time" jobs are spawned to download each asset to TruckMate. Also: spawns a job to check the unit status to determine in/out of service notices.

-

Get Accounting Lists: retrieves list of accounts payable, accounts receivable, GL inventory updates and GL expense updates. Again, if entries are found, individual jobs are spawned to collect the details.

-

Update Positions: uploads the current positions of units to TruckMate.

-

Update Odometers: uploads current ODO readings to TMT Fleet Maintenance.

One Time Jobs

-

Get Work Pending: retrieves list of assets that have 'Work Pending' status. 'Work Pending' occurs when an asset requires maintenance or repair, but a part or resource is unavailable. The asset remains 'Active' and in service but will be put into the shop at the first opportunity. TruckMate has no real equivalent for this status.

-

Get PM Due: retrieves list of assets that require preventative maintenance. Similar to TruckMate Special Events, but no date given so cannot be used for that purpose. Instead, see Get Unit Status.

-

Get Unit Detail: gets information about a specific unit. Called by 'Check TMT Fleet Maintenance Job'. Unit information is stored in TMT FLEET MAINTENANCE_ASSETS_XREF and copied to the relevant resource tables.

-

Get Unit Status: gets information about the status of specific units. Called by 'Check TMT Fleet Maintenance Job'. Status is either 'IN-SHOP', 'PLAN', 'PENDING' or 'ACTIVE' (but since TruckMate does not have a status equivalent to 'PENDING', it is treated as 'ACTIVE'). 'IN-SHOP' and 'ACTIVE' statuses serve to generate in/out of repair notices, typically by setting the status of the unit appropriately. 'PLAN' indicates units that have been scheduled for work and will generate a Special Event notification in TruckMate.

-

Sync Master: uploads information about a specific asset to TMT Fleet Maintenance. Called by 'Update Master Files'. As well as uploading to TMT Fleet Maintenance, asset is also directly added to TMT FLEET MAINTENANCE_ASSETS_XREF to prevent it from being downloaded later by 'Get Unit Detail'.

-

Get Account Detail: gets information about individual accounting transactions. Called by 'Get Accounting Lists'. GL Expense and GL Inventory adjustments are copied to the GL_TRANS table. AP Invoice adjustments are copied to AP_BILL and AP_BILL_EXP tables. AR Invoice adjustments are (by default) converted into Freight Bills (FBs) and stored in TLORDER. However, this process is controlled by a stored procedure (SP) so it could be rewritten to store the AR invoice in one of the RM tables.

-

Set Meters: this is a general purpose job that sets a particular metric for a specific asset. For example, it is used by 'Update Odometer' to export odometer readings to TMT Fleet Maintenance.

-

Set Physical Status: sets the status of assets, including Location. Called by 'Update Positions'.

-

Get Meters: Reverse of 'Set Meters'. Not currently used.

-

Get Unit XRef: retrieve list of units with both TruckMate and TMT Fleet Maintenance IDs. Not currently used.

-

Get Shop XRef: retrieve list of shops with both TruckMate and TMT Fleet Maintenance IDs. Not currently used.

-

Get Physical Location: retrieves location of assets from TMT Fleet Maintenance tables. Not currently used.

Data Transfer Example

-

TruckMate Service Host will periodically download new units from TMT Fleet Maintenance. A "new" unit is defined as one that has been added since the time of the last download. During the initial run, the last download time is arbitrarily set to 10 years in the past in order to get all of the units.

-

Initially, the "Error Log" module has a green checkmark for an icon. This indicates that there are no entries in the log.

-

When the system retrieves a list of new units, it sorts the list by 'Type' and presents it to the user.

-

If the user does not want to import that particular unit, it should be unchecked. By default, everything is checked.

-

When the list is correct, the user can select 'Update' to import the units. Since this program is designed to run autonomously, an 'Auto Accept' feature has been added that will automatically accept the default list after 2 minutes.

-

If errors have occurred during data exchange, they will be displayed in the error log. If the log contains messages, the icon will change to a red "X".

-

Double clicking the module will reveal the Error Log window. This form describes the SQL statement that led to the error and the error message. From here you can review the errors, delete them from the log, or edit the SQL and try running it again.